It took only ten years for landfills to vanish in Finland. They were replaced by incineration plants. Now we’re renewing our composting plants. They first produce biogas, then compost mulch.

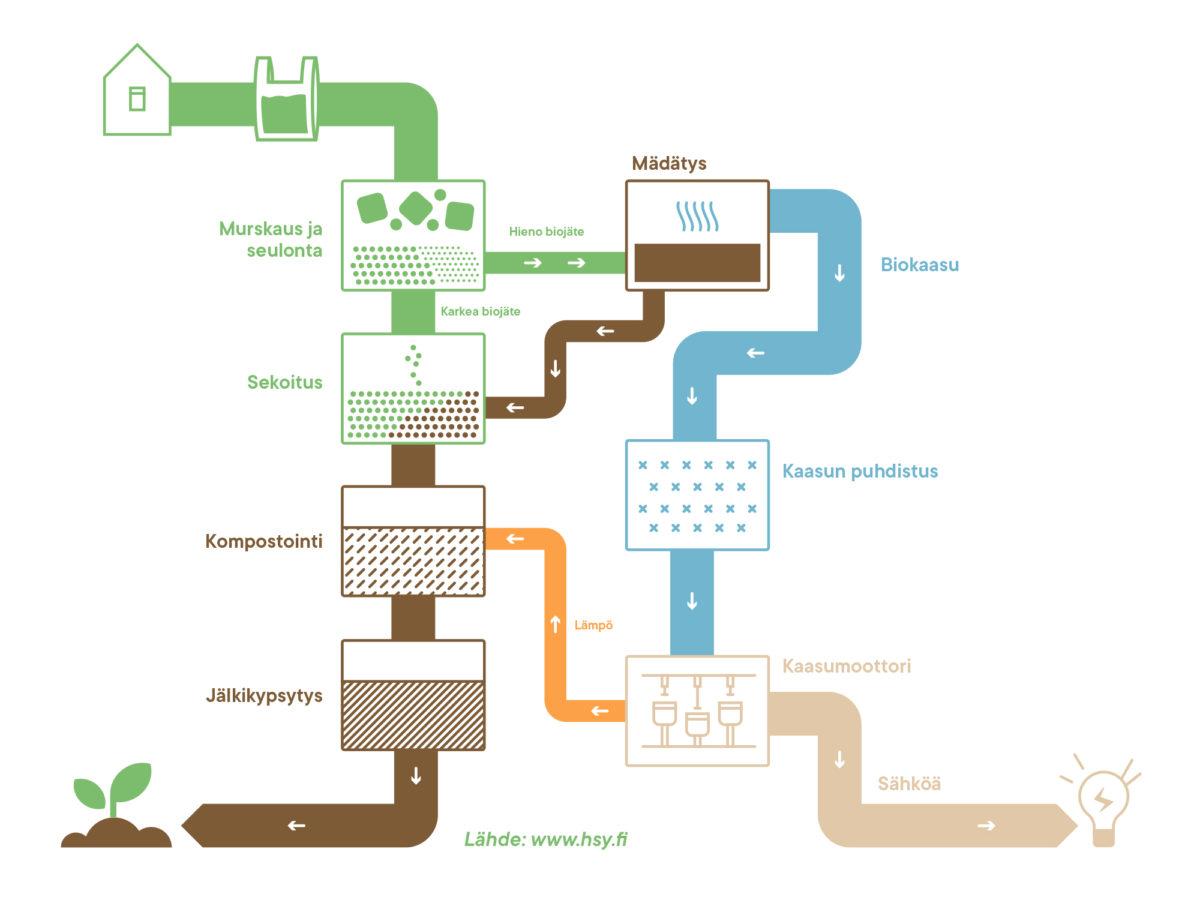

The newest plants process biowaste into both compost mulch and biogas. The biowaste is crushed before being sorted by coarseness. The coarser grades are sent directly down the composting tunnel,

while the finer grades are sent to the digestion process, where biogas is recovered. This gas is cleaned and used to generate heat, electricity or both. In some places, biogas is processed into transport fuel. At combination plants, any remaining digestate is sent for composting HSY’s biowaste treatment facility in Ämmässuo is an example of a combination plant. Its process is the inspiration for this article’s illustrations.

Temperatures reach over 60°C during industrial composting. The waste fraction is then taken outside for afterripening. Depending on the facility or location, post-composting in an outdoor stack may last for anything from a few months to two years.

This is how your leftovers warm homes and power cars. They’re used to nourish fields and build parks. When you sort your biowaste into Bioska bags, it will be used in the best possible way.

“Biogas is used to warm homes and power cars”

Read more articles from Bioska

Waste processing is a growing business

More food is produced than is consumed. Unfortunately, the amount of waste from food production is only expected to grow. Various factors are affecting this, such as people adopting plant-based diets and an increase in processed food and take-aways.

Read more

Five-star leftovers

Biowaste is becoming an increasingly valuable raw material. Waste food restaurants have already been established in Finland. Apps, and at least one webstore, have been developed to sell waste food before it goes bad. In many homes, biowaste is also being recycled and processed in more creative and refined ways.

Read more